What is current production technique for solar LED lighting ?

With the gradual approach of fossil fuel crisis and sharpness of environmental problem, to develop renewable energy is extremely urgent. Solar energy is unlimited storage, widespread existing, cleaning exploitation and economic developing, etc, which makes it become ideal alternative energy. In the meantime economic development, energy-saving is also the important problem that society faces. LED is the fourth generation lighting resources, it is fast utilized for application because of energy-saving product and environmental friendly product.

1. The present developing of silicon solar cells.

Basing on abundant storage of silicon, the rapid developing of advanced technology accumulated by micro-electronics industry and electric technology of silicon materials, makes silicon solar cells occupy market shares above 90% in solar PV industry.

1) Monocrystalline solar cells.

Presently, in the world, the silicon ingot of pv industry silicon solar cells on the material is to adopt inferior silicon and its top and tail of semiconductor industry, semiconductor silicon fragment, producing monocrystalline solar cells after getting through restoration of monocrystalline furnace, the purity of this silicon materials mainly is from 6N to 7N, including the monocrystalline silicon which specially produces solar cells, such as neutron ascendant mix with czochralski monocrystalline silicon. The growth technology of monocrystalline silicon is main czochralski and floating zone method. Czochralski is inevitable to attract into some oxygen because of the application of silica crucible, oxygen precipitates is recombination center, then to reduce lifespan of minority carrier material. Floating zone method combines zone-refine and manufacturing monocrystalline silicon, which can grow high pure and no defect monocrystalline silicon. In the present world, the highest efficiency of czochralski silicon is 24.5%, the zone melting monocrystalline silicon is 24.7%, currently, the efficiency of monocrystalline solar cells is around 18%-20%.

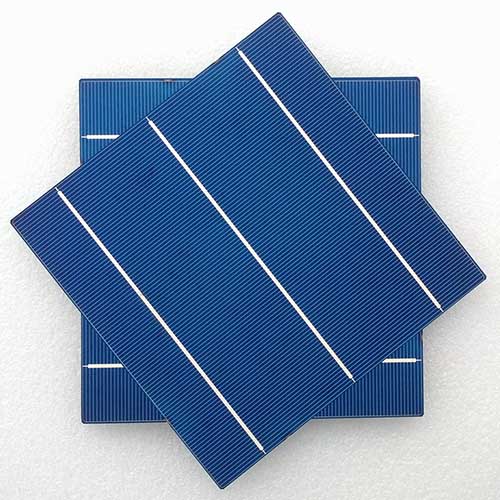

2) Polycrystalline silicon solar cells.

Polycrystalline silicon solar cells have omitted the costly process which manufactures monocrystalline silicon, it saves silicon materials, it has lower request for raw material, easy to grow big size square ingot, low power consumption when growing, the cost of silicon wafer has been reduced, then greatly decreases the production cost of solar cells. Its defect is having crystal boundary, dislocation, vacancy and impurities, etc, which has some influence to the conversion rate of polycrystalline solar cells. The preparation method of polycrystalline silicon mainly includes Casting and electromagnetic Casting methods, The Freiburg solar power system research institute in Germany has successfully made polycrystalline solar cells whose efficiency is over 20% by polycrystalline silicon materials, Presently, the efficiency of industrialization polycrystalline solar cells is around 17%-18%. Although its efficiency is less than monocrystalline solar cells, the production output of polycrystalline solar cells had exceeded monocrystalline solar cells to be mainstream of silicon materials because of cost advantage.

3) Ribbon silicon solar cells.

Monocrystalline and polycrystalline are bulk materials, they need be cut when to manufacture solar cells, to adopt internal cutting can cut monocrystalline silicon ingot to be silicon wafer, nearly 50% of silicon materials has been wasted, cost is very high. The loss can be decreased to be around 30% via multi-line cutting technology, but it also can make materials have wastage. In order to avoid this loss from cutting, the technique is researched from liquation silicon fluid to directly grow ribbon silicon, some has been used for practical production. To adopt non-cutting ribbon silicon as substrate can improve the use ratio of silicon from 20% to be above 80%. The growth method of ribbon silicon has Edge-defined Film-fed Growth, Strip Growth, Ribbon Growth on the substrate, Powder Wafer Growth and Webbed Growth, etc. The Edge-defined Film-fed Growth method has realized industrialization, it is the most mature ribbon silicon technology at present, the efficiency of big size (10cm*10cm) solar cells has reached 14.3%. In Germany, Fraunhofer solar system research institute adopts Optical Heating Technique to melt silicon powder directly to be thin ribbon silicon, then use it as low cost substrate for silicon cells, the most efficiency of this silicon cells is 11.2%.

4) Silicon thin film solar cells.

(1) Non-Crystalline thin film solar cells.

The materials of non-crystalline thin film solar cells are a kind of alloy of silicon and hydrogen, Under some areas of visible light, the absorption coefficient of non-crystalline silicon is higher monocrystalline silicon than around 10 times. In order to require the absorption condition, the thickness of monocrystalline silicon is 100um, while non-crystalline silicon just need 0.5-1.0um, greatly reducing the request quantities of materials. Simultaneously, Integrated technology can be adopted for process of solar cells production to complete solar modules at one time, it omitted these independent production processes for materials, devices and solar modules. The multilayer technology can be used to decrease the request of material quality, etc. Non-crystalline silicon mainly is made by Vapor deposition method which can be classified as glow discharge decomposition method, sputtering method, Vacuum evaporation, Photochemistry vapor deposition and hot filament, etc, Plasma enhancing chemical vapor deposition (PECVD) has been widely applied.

As non-crystalline silicon thin film solar cell materials have Staebler-Wronski effect, nono-crystalline silicon thin film solar cells would have power degradation after long time to be radiated by solar, then leading to the efficiency decreasing of whole solar cell, deposition rate is low and difficult for subsequent process, these factors extremely limit the application of non-crystalline thin film solar cells.

(2). Polycrystalline silicon thin film solar cells.

Polycrystalline silicon thin film is made of many small crystals with different crystal tropism which grows on substrate, polycrystalline thin film solar cells are the new generation solar cells which incorporate the high conversion rate and long lifespan of monocrystalline and polycrystalline solar cells, and the relative simple for manufacturing craft of non-crystalline thin film solar cell materials. Presently, the manufacturing methods of polycrystalline thin film mainly are Low pressure chemical vapor deposition, Hot filament chemical vapor deposition, Solid phase crystallization, Laser-induce crystallization and Metal induced crystallization, etc. Polycrystalline thin film solar cells have very attractive prospect in these aspects which are improving efficiency of solar cells, energy-saving and dramatical decreasing cost. In China, research institute is just starting up.

2. The current developing for LED lighting.

LED lighting resource is as light emitting diode (LED) as lighting resource, belonging to Solid State Lighting. The main advantages of LED are high lighting efficiency, low power consumption (it is just one eighth of incandescent light under the same as brightness effect), long lifespan (its theory lifespan can be up to 100 thousand hours, lifespan of product is over 50 thousand hours as usual), high brightness lighting, low heat emitting and fast response (its response time is about some microsecond). The main application of LED lighting resource is mainly for landscape light, decoration light, back lighting, road lighting, indoor lighting, automobile light, portable lamp and projection light, etc.

Presently, the main questions of LED lighting include: Luminous flux need be improved furtherly, the efficiency of current LED chips is about 20%-30%, still remain big space to improve; LED lighting still has some difference with natural lighting, there are too much blue light in LED, uneven color space is caused by halo effect, still having some photo-biological safety problem; Price is still relative high, in recent years, LED is developed toward high efficiency with low cost, which would benefits its application for lighting field.

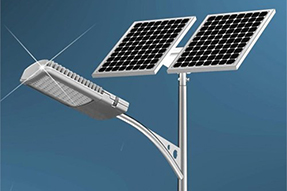

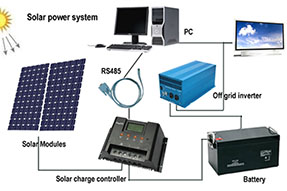

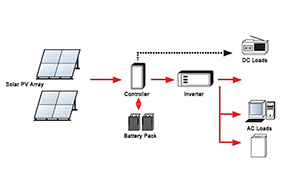

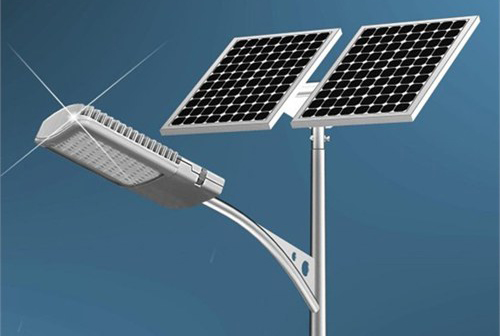

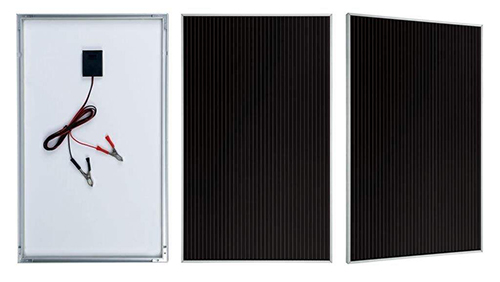

3. The Current developing of solar LED lighting.

Modified Siemens Method is main technique for manufacturing polycrystalline silicon at present, production output has occupied 70%-80% of the world total output. In China, the core production technology is still low, especially the production core technology of polycrystalline silicon is grasped by some large enterprises in the world, the polycrystalline production cost of most China’s companies are higher about US$10/KG than other Countries. The main market of China’s pv module is in overseas, the developing of internal market is slow.

Most of enterprises focus on the manufacturing and assembling of solar cells, these middle chain is low profit, which causes the developing basement of solar cells is not very strong. Therefore, it is important to improve equipment performance, stability and craft ability. The LED production equipment and technology still lag Europe and North America, then China’s enterprises still need make a large of investment to research more advanced technology for production. Fortunately, after efforts of many years, China has got large achievement for production technology. Recently, most of solar application products are exported from China to whole of the world.

4. Prospect of Solar LED Lighting.

The pv industry and LED industry are being innovative for market demand, especially for the production of polycrystalline silicon, the core production technology of LED chips have got extremely progress. LED is energy-saving Lighting source, solar power is renewable energy, their combination is the developing technology for society.

In a world, Solar LED lighting is promising in market, with mature technology for various of materials production, gradual decreasing of production cost, greatly support from various Countries’ Governments, Solar LED light will be widely applicable for various fields for human’s lives.

Bingsolar Power, 4th, December, 2017