What is the composition and working principle of solar power system ?

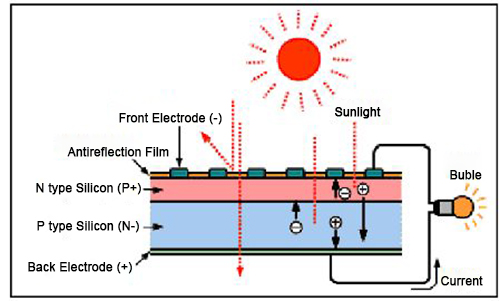

The energy conversion unit of solar power system is solar cells. The working principle of solar cells generation is photovoltaic effect. Solar cells absorb sunlight energy when it is radiated by solar, to produce photoelectron named as electron-hole pairs. The photoelectron and electron hole would be separated under the function of electric field built-in battery, the both ends of battery appear the accumulation of opposite charge, namely it produces “photovoltage”, this is photovoltaic effect. If wiring out electrode and connecting with loads on both sides of built-in electric field, the loads would have transmission of Photocurrent, then to get the output of power. In this way, solar radiation can be directly converted into power electricity.

1. The composition of solar power system.

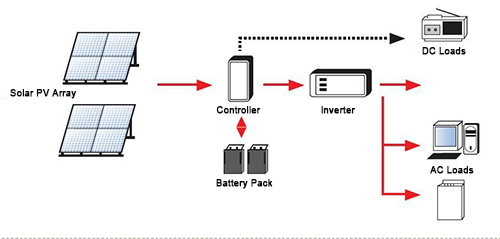

The composition of off-grid solar power system is as below to show:

-1) The Solar PV Array.

Solar cell is the smallest unit of photovoltaic conversion, its size is 125*125mm or 156*156mm. The working voltage of solar cell is about 0.5V, working current is about 20mA~25mA /cm^2, it can’t be independently used for power supply. After series and parallel connection for solar cells, they would become solar module which can be independently used for power supply. After series and parallel connection for solar modules, they would become solar pv array which can meet the output power that loads require.

(1) Brief introduction. The voltage that one solar cell just can produce about 0.5V which is far less actual requirement. In order to meet actual requirement, solar cells need be connected to be solar modules. Solar panel includes some quantities solar cells, these solar cells are connected by electric lead. The quantities of solar cells are 36pcs or 40pcs in one solar panel, then the voltage that the solar panel produces would be about 16V which can be efficient to charge battery whose rated voltage is 12V.

Solar cells are connected by electric lead and sealed to be solar modules, it can be corrosion prevention, wind withstanding, hail proof and rain-proof, etc, it is widely used for various fields and solar systems. When single solar module can’t meet more high voltage and current that application fields require, solar modules can be gathered as solar pv array to get the request voltage and current.

(2) Encapsulated Type. The reliability of solar cells mainly rely on these abilities of corrosion prevention, wind withstanding, hail proof and rain-proof ect. Its potential quality problem is the edge sealed and junction box backside of solar module. The encapsulated type of solar cells mainly includes below two types. The first type is double glass to seal. Both frontside and backside of solar panel are tempered glass, solar cells are inlaid a layer of polymer. The main problem of this encapsulated type is the connection of glass and junction box, this connection has to get through the edge of tempered glass, it is costly to punch on tempered glass. The second type is glass and aluminum alloy to seal, frontside of this solar module is tempered glass, its backside is alloy sheet. The main function of alloy sheet is moisture proof and antifouling. In solar module, solar cells and junction box can be connected by electric lead.

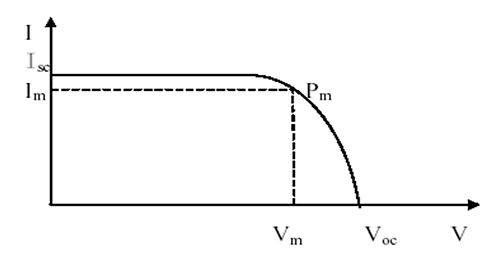

(3) Electrical Performance. The main electrical performance of solar module is the performance of Current and Voltage, also said IV curve, below diagram presents that the relation of Current and Voltage under given solar radiation via solar panel to transmit.

I-Current, Isc-Short Current, Im-Maximum Current, V- Voltage, Voc- Open Circuit Voltage, Vm-Maximum working Voltage, Pm-Maximum Power.

When V=0, its short current is Isc. When I=0, its open circuit voltage is Voc. The output power of solar panel equals to the multiplying of Current and Voltage, namely P=VI.

When the voltage of solar panel increases, such as via improving the resistance value of loads or voltage of solar panel start to increase from 0, the output power of solar module also start to increase from 0. When voltage reach some value, the power reach its maximum, at this time to continue to increase resistance value, power would get through the maximum point decreasing to be 0 gradually, at this time, its voltage is Voc. At this maximum output power, we said it as Maximum Power point, its voltage is Vmpp, Its current is Im, its power is Pm.

With the increasing of solar cells temperature, Voc is decreasing, the voltage of each solar cell would decrease about 5mV if its temperature increases about 1 degree, the typical temperature coefficient is -0.4%/℃ at the maximum power output, Namely, the maximum power output would decreases 0.4% if temperature of solar cells increases 1℃.

(4) Performance Test. As the output power of solar panel depends on solar irradiation, solar spectrum distribution and solar cells temperature, the test of solar panel is under standard condition (STC), the test condition was defined as 101 standard by European Commission, its condition: Irradiation is 1000W/m^2, spectrum is AM1.5, solar cells temperature is 25℃. Under this condition, the output power of solar panel is called as Peak Power (Wp). In many cases, the peak power of solar panel is tested by Solar Simulator and comparing with International Certification Authority’s standardization Solar cells. It is very difficult to test its Peak power in outdoors, because actual solar spectrum that solar panel receives depends on atmospheric conditions and position of solar. In addition, the solar cells temperature is variation during test, the random error would be 10% or more if test in outdoors.

(5) Hot Spot Effect and Bypass Diode. Under some condition, if a branch of series connection is shadowed, this solar panel would be treated as loads to consume the power that other solar panels produce. The solar panel which is shadowed would heat at this time, this is Hot Spot Effect. This effect would seriously destroy solar cells. Some power or all power which is produced by solar cells radiated by sunlight could be consumed by the solar cells which are shadowed. In order to avoid solar cells being destroyed by Hot Spot Effect, a Bypass Diode need be paralleled connection between the position pole and negative pole of solar module.

(6) Junction Box. Junction Box is an important component, it protects the interface of solar cells and external, and the electric lead of various internal connection and other system components. Junction box includes a connecting box and one or two Bypass Diode.

(7) Reliability and Lifespan. The best way to inspect the reliability of solar cells is test in outdoor, but this test need get through a very long time. In order to test its reliability by lower cost and small time under the same working condition, a kind of new-type test method is developing, the method is to accelerate lifespan, this method is designed mainly according to the relevancy of outdoor test and the acceleration test which is conducted in pass, basing on theoretical analysis and referring to other electronic test techniques and the test standard of IEC standardization committee of solar photovoltaic system. A full set of reliable test method is described in 503 Item of IEC Standard. This standard includes below test content: UV Lighting Test, High Temperature Exposure Test, High Temperature/High Moisture Test, Frame Torsion Resistance Test, Mechanical Strength Test, Hail Test and High Temperature Cycle Test.

The expectation lifespan of solar panel is at least 20 years, the actual lifespan depends on structure of solar module and local environmental condition.

-2) Anti-reverse Charging Diode.

It is also called as Block Diode, its function is to avoid battery pack discharging to solar pv array when solar pv array don’t produce power under rainy days and nights. It is series connected inside the circuit of solar pv array, having unilateral conduction function. The Diode need withstand enough high Current, the voltage drop of forward direction need be small, the Saturation Current of reverse direction need be small. Usually, suitable commutation diode can be selected.

-3) Battery Pack. Its function is to store the power that solar panel converts and can discharge for loads at any time. The battery pack is required as low self-discharge rate, long lifespan, strong deep discharge capacity, high efficient charging, less maintenance or non-maintenance, wide working temperature range and low cost. Presently, the storage battery which is special for solar generation system mainly is Lead-acid battery and Cadmium-nickel battery in China. For Lead-acid battery whose capacity is above 200Ah, usually fixed and Industrial Maintenance Free Lead-acid battery are used. For Lead-acid battery whose capacity is below 200Ah, Usually small maintenance free Lead-acid battery is used.

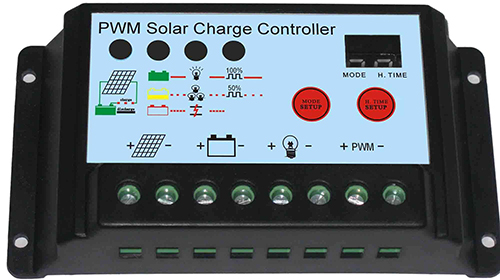

-4) Controller. Controller is one of core components for solar pv system. The solar pv control should have below functions: (1), Signal Detection. To detect the state and parameters of various devices and units in solar pv system, to provide basis for system analysis, control and protection, etc. These data includes input voltage, charging current, output voltage, output current and temperature increasing of battery, etc. (2), The optimum charging control for battery. Controller can confirm the optimum charging method according to current solar condition and battery electric charge state, to realize high efficiency and fast charging, meanwhile, need consider the lifespan effect from charging methods. (3), Management of Battery Discharging. To manage battery discharging process, such as loads to control auto powering on or off, realizing to soft boot, to prevent terminal voltage of battery sudden decreasing to make error protection when connecting with loads. (4), Devices Protection. The appliances which connect with solar pv system need be protected by controller at some conditions, if it is not control timely, solar pv system or electric devices would be damaged. (5), Fault Diagnosis and Positioning. It can automatic to detect fault type, indicating fault position when solar pv system has some malfunction. (6), Indicator for Operation State. Via indicator light and monitor to indicates the operation state and malfunction information of solar pv system.

Solar pv system is working under management of controller. Various of techniques can be adopted to realize control function, such as logic control and computer control. Intelligent control mostly adopts computer control method.

(1) Logical control is the controller which is as simulation and digital circuit as main structure, by test electric parameter which is relative with solar system, then computed and judged by circuit to realize the special control function.

(2) Computer Control Method. It can comprehensively collect simulation data and power on/off state of solar pv system, efficiently utilize the fast operation and judgement ability of computer, to realize optimum control and smart management. It is made up of hardware circuit and software system. The interaction and coordination of hardware circuit and software system can realize the control and management to solar pv system. Hardware circuit is CPU as core, which is via the measuring circuit of current and voltage, state measuring circuit to get the relative current, voltage, temperature and working state and operation instruction of various units, via simulate input channel and on-off input channel to transmit information into computer. On the other hand, this adjustment signal and control order which are sent by computer getting through operation and judgement can be transmitted to actuator by simulating input channel and on-off input channel, via actuator to make relative adjustment according to the order that it gets. Software system is specially designed for some solar pv system, it consists of scheduler and many software modules or function which can realize special function. Schedule is according to current state of system, by setting mode to complete detection, operation, control, management, warning and protection function, etc, according to setting charging mode to control charging and manage discharging. As computer, especially for Single Chip microcomputer, is cheap, flexible setting, high performance, most of controllers adopt single chip technique to realize its control function at present solar pv station.

-5) Inverter.

Inverter is the device which can convert DC into AC. As the power of solar panel and battery is DC, the inverter is inevitable when loads is AC appliances. The basic requirement for inverter: (1), It can output the current with stable voltage. No matter what input voltage has fluctuation or loads has change, it still can have some accurately stable voltage, usually, it is +_2% at static state. (2), It can output AC with stable frequency. The AC is required to reach some stable frequency accuracy, usually, it is +_0.5% at static state. (3), The output voltage and frequency can be adjusted at some range. Usually, the range of adjustable voltage is +_5%, the range of adjustable output frequency is +_2Hz. (4), It has some capacity for overload, usually, it can be overload about 125%~150%. It should be able to stand 30s when overload is 150%, it should be able to stand above one minute when overload is 125%. (5), The waveform of output voltage should have more less harmonic wave, usually, the distortion rate of output waveform should be controlled within 7%, to benefits for shrinking the size of filter device. (6), It should have short-circuit protection, overload protection, over-heat protection, over-voltage protection, undervoltage protection and warning function. (7). Its starting should be stable, small starting current, stable and reliable operation. (8), It should have small loss for conversion current, high invert frequency, it is above 85% as usual. (9), It should have fast dynamic response. The operation type of inverter can be classified as off-grid inverter and grid-connected inverter. Off-grid inverter is used for off-grid solar pv system, it can provide power supply for independent loads. Grid-connected inverter is used for grid-connected solar pv system, transmitting power to public grid. According to output waveform, inverter can be classified as square wave inverter and sine wave inverter. The circuit of square wave inverter is simple, cost is low, but it has more harmonic wave, usually, it can be used for those loads whose power is some hundred and request for harmonic wave is not high. The cost of sine wave inverter is high, but it can be used for various loads. From long term, The transistor sine wave inverter will be development mainstream.

-6) Measure Equipment.

Regards to small solar power system, just need take some simple measure, such as voltage of battery and current of charging and discharging, the amperemeter and voltmeter are installed on controller. For solar communication power system, pipeline cathodic protection system, other industrialization power system and large and medium-scaled solar power station, it need test more parameters, such as solar irradiance, environmental temperature, state of charging and discharging, etc, sometime it even need have function for remote data transmission, data printing and wireless control, then it need allocate data collection system and microcomputer monitoring system for solar pv system.

2. Operation Mode.

As Sun resources is dispersive, and appear everywhere, solar pv system is very suitable for independent power supply, such as for remote village and home solar power supply system, solar lighting system, solar pump system and solar communication power system, etc. Solar pv system can be combined with other generation system to be hybrid power supply system, such as wind-solar hybrid generation system, solar-wind-petroleum hybrid generation system, etc. As the cost of wind generation system is low, solar and wind have many complementarities in many districts, then to numerously decrease battery capacity, therefore, the investment of solar-wind hybrid system is less about one thirds than independent solar pv system. The DC that solar system generates is converted by inverter to transmit to public grid. Grid-connected solar power system can be classified as Passive grid-connected solar pv system and Active grid-connected solar pv system. The passive grid-connected solar pv system don’t have storage system, the power which is transmitted to public grid completely rely on solar irradiation state, which can’t be adjusted. Active solar pv system has storage system, it can connect with public grid or disconnect with public grid according to requirement. Practice has proved that grid-connected solar pv system can regulate peak load to public grid, to improve the voltage stability of terminal of public grid, improve power factor of public grid and efficient to eliminate the noise wave of public grid, it has many superiorities.

Bingsolar Power, 8th, December, 2017